Benchmark Spray Combustion Database

Project Description

Background

Control of process efficiency and the formation of species byproducts from industrial thermal oxidation systems (e.g., power generation and treatment of process liquid chemical wastes), is generally based on a priori knowledge of the input stream global physical and chemical properties, desired stoichiometric conditions, and monitoring of a few major chemical species in the exhaust. Optimization of the system performance relies on computational models and simulations that help provide relevant process information in a cost-effective manner. In general, there is a dearth of reliable data for specifying model initial/boundary conditions, and a need for experimental/numerical comparative analysis of conditions within the reactor. The reactor volume is precisely the region that requires a better knowledge base to enable optimization of the chemical and thermal processes, and control of particulate and gaseous emissions. System performance is dependent strongly on the quality of liquid atomization, aerodynamic design, and the degree of liquid/air mixedness. The need to provide in-situ, real-time data on the characteristics of the droplet field and flame structure, and its interrelationship with the system operating conditions (e.g., desired stoichiometry), heat transfer, and particulate/gaseous byproducts is crucial for the development and calibration of advanced computational models, diagnostics, and instrumentation, and the efficient operation of high-temperature process systems.

Methodology

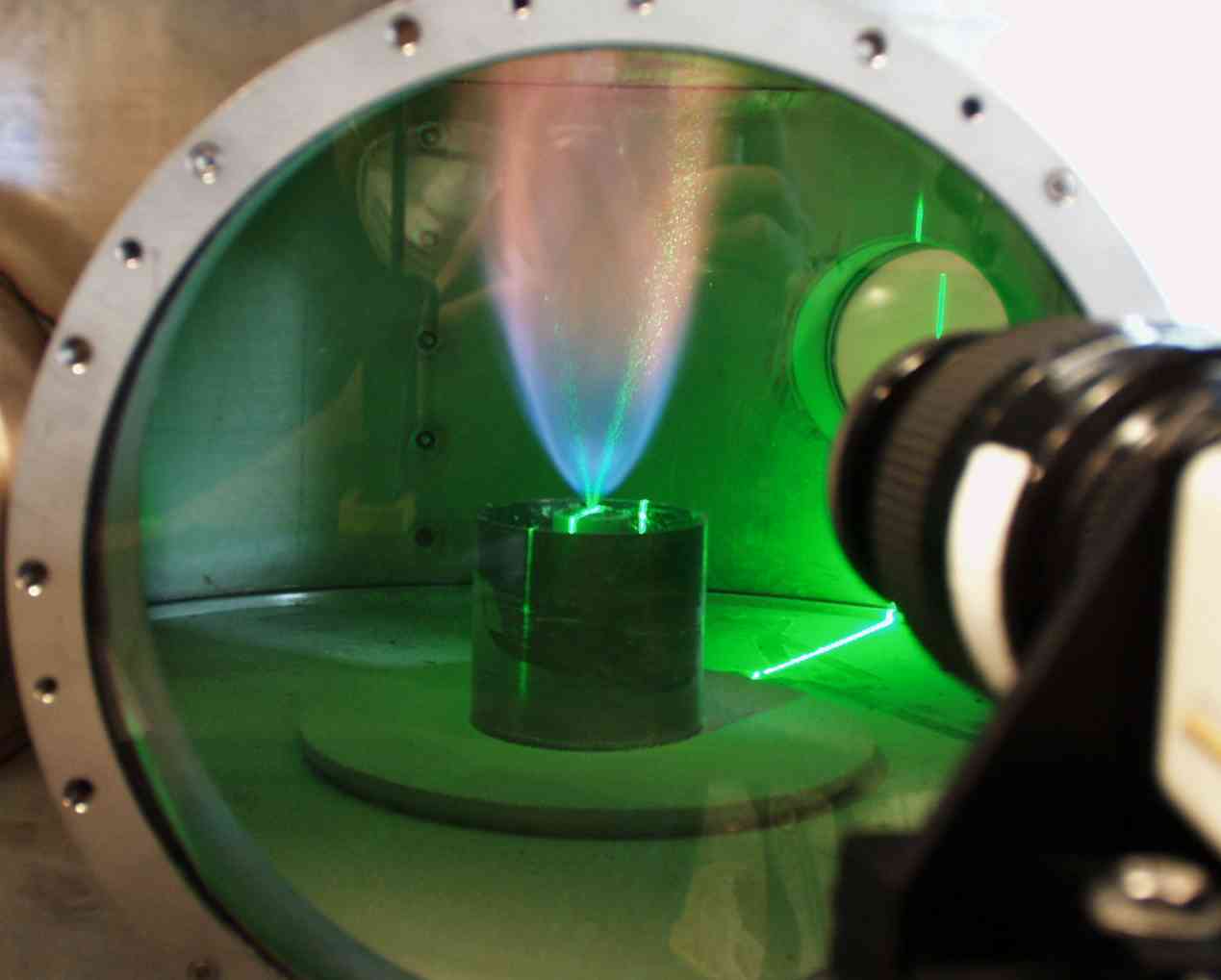

There is a dearth of on-line experimental data inside industrial combustion reaction systems due to the harsh and inaccessible environment. There was a critical need for a laboratory-scale, spray combustion research and diagnostics test bed to provide standardized, reliable, and statistically significant benchmark experimental data for 1) input and validation of multiphase, reacting computational fluid dynamics (CFD) models, and 2) application and calibration of state-of-the-art sensors under development by numerous industrial, academic, and governmental research groups. To this ends the NIST spray combustion test bed (SCT) was developed to monitor the combustion process not only in the exhaust stream but also upstream in the flame and near the burner. This characterization of the combustor using a variety of state-of-the-art diagnostics was used to improve the measurement science and provide statistically significant data sets for numerical simulations and instrument calibration.

Approach

The NIST SCT evolved into a well-characterized and controlled system that was able to handle different 1) process liquid fuels and wastes, 2) atomizer designs, and 3) combustor configurations. A variety of diagnostics were employed to the input fuel stream (fuel composition), spray flame (droplet size, velocity, and temperature), and flame emissions (particulates and chemical species). The measurements were used to provide reliable benchmark data for process optimization and control, real-time in-situ sensor development, and input/validation of numerical simulations. A coupled experimental/computational approach was implemented by involving modelers from our industrial partners directly in the formulation of the experimental program.

Laboratory Capabilities

The NIST SCT permitted examination of the effects of air swirl, atomizer design, fuel type, and air preheat on spray structure, combustion and emission characteristics. Experiments were carried out under a variety of conditions, where the flow parameters (air flow velocity, swirl number, inlet air and fuel temperature) and fuel injector characteristics (fuel flow rate, spray angle, atomizer configuration) were variable over a wide range.

Spray Combustion Facility

The facility included a swirl burner with a movable 12-vane swirl cascade. The cascade rotates simultaneously to impart the desired degree of swirl intensity to the combustion air stream that passed through a 101 mm diameter passage and coflows around the fuel nozzle. Combustion air was supplied via a 95 L/s compressor. A simplex pressure-jet (producing hollow-cone spray) was used to investigate a injector geometry effects on combustion characteristics. The fuel nozzle was nominally operated at total air and fuel flow rates of 64.3 kg/h and 7 kg/h, respectively. Methanol was used as the fuel because the chemical kinetics are well known and it is non-sooting. Fuel storage was available in tanks ranging in size from 20 L (which allows burning of different premixed mixture compositions). The burner was enclosed with a stainless steel chamber to allow for controlled evaluation of the boundary conditions. The chamber height is 1.2 m and the inner diameter is 0.8 m. Several ports were strategically located to provide the required access for a variety of probes and optical arrangements.

A stepper-motor-driven, three-dimensional traversing system translates the burner assembly in the vertical and horizontal directions, and allows measurement of profiles of the spray properties, e.g., droplet size, number density, velocity, and gas species concentrations at selected spatial locations downstream of the nozzle. The burner can be moved over 500 mm in the vertical direction at a resolution of 0.05 mm, while providing overall movement in one horizontal direction of up to 200 mm with a resolution of 0.01 mm. The traverse in the other horizontal direction also provides millimeter accuracy over a wide range and is used primarily for precise alignment of the burner assembly with the surrounding optical equipment. All optical diagnostics are fixed in position about the burner assembly and the burner translates independently of the optical equipment.

Diagnostic Capabilities

A combination of nonintrusive optical diagnostic and intrusive probing techniques were available to obtain comprehensive data on spray combustion characteristics. A two-channel phase/Doppler interferometer was available for measurement of droplet size and velocity distributions, as well as statistical information (e.g., droplet mean size, number density, and velocity) on a spatial and temporal basis. The time-based capability allowed spectral analysis of results for detection of temporal features of the spray. A 3-D particle image velocimetry system was used to characterize the burner inlet combustion air flow, including the three components of gas-phase velocity and the turbulent velocity fluctuations. Interpretation of the experimental measurements was facilitated by acquiring a qualitative understanding of the global spray characteristics. To this end, several flow-visualization techniques were also available for direct observation of the spray.

An on-line Fourier transform infrared (FTIR) spectrometer was available for extractive sampling of chemical species that were found in the combustor emissions. The gas sampling system consisted of a water-cooled stainless steel sampling probe (with an inlet throat diameter of 1 mm, outer diameter of 12.7 mm, and hemispherical-shaped head) that aerodynamically quenches the entering gas flow. Heated lines, maintained at 420 K, prevent the gases from condensing in the lines before reaching the analyzers. An ice trap placed immediately downstream of the sampling probe, and an permeation- type gas dryer placed further downstream in the gas train are used to condense the water and introduce dry sample gas to the emission monitors. Gas species measurements were supplemented by intrusive temperature measurements with sheathed thermocouples.